Charging system with 24/7 technical support

Charging system with 24/7 technical support

Specifications

Load capacity: Up to 300 kg.

Material dimensions: Maximum of 10ft x 5ft.

Power supply: 6KVA / 220VAC / 50Hz.

Pneumatic feed: 72-87 psi, flow ≥14.1 CFM

Working environment: Temperatures from -10°C to 45°C, humidity ≤95% RH

Specifications

Load capacity

Up to 300 kg

Material dimensions

Maximum of 10ft x 5ft.

Power supply

6KVA / 220VAC / 50Hz.

Pneumatic feeding:

72-87 psi, flow ≥14.1 CFM

Work environment

Temperatures from -10°C to 45°C, humidity ≤95% RH

Outstanding Features

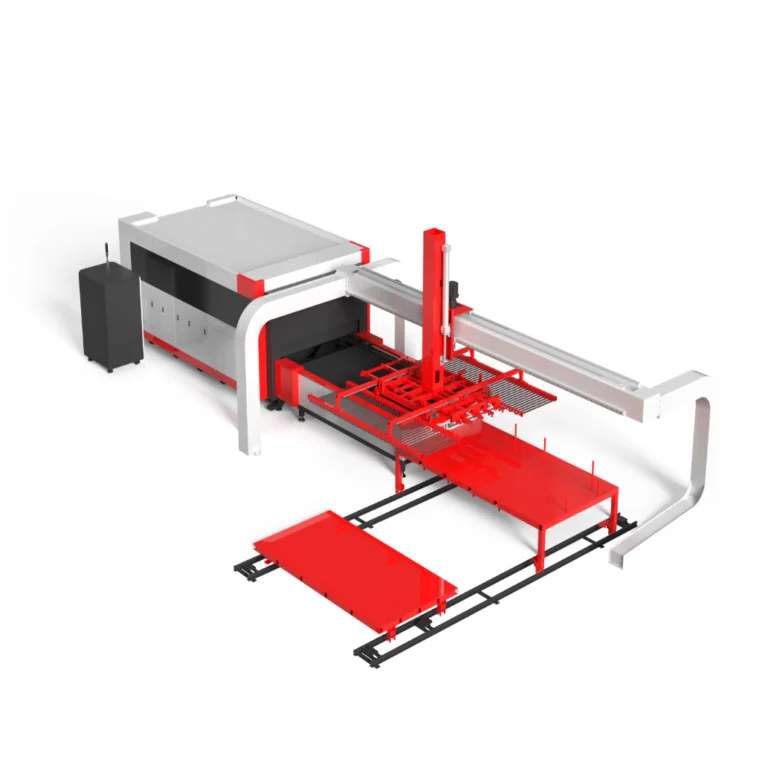

The loading arm features high-speed, low-noise linear guides combined with a high-torque servo motor for smooth sliding and lifting. Its swing arm mechanism, driven by a precision cylinder, offers a swivel range of 120° (60° to each side).

Designed to handle up to 300 kg weight, ideal for metal sheets up to 10ft x 5ft.

Equipped with 15 oil-resistant vacuum suction cups, including a pneumatic plate separation kit to optimize the handling of thin materials. Flexible configuration allows adaptation to different plate widths.

It uses an Omron programmable controller and a high-precision portable touch screen. It includes functions such as fault diagnostics, alarms, and manual and automatic programming, offering maximum intuitiveness and ease of use.

The automatic on/off system optimizes energy consumption, contributing to a more environmentally friendly operation.

General Features

Our loading and unloading systems

FORZA Lyfter

FORZA Lyfter II

Material Handling Safety

Improves operator safety by reducing handling risks, especially with heavy or oversized materials.

Cycle Time Reduction

Minimizes waiting times between processes, speeding up production flow for greater efficiency.

Handling Automation

Automated system for loading and unloading materials, reducing the need for manual intervention.

Facilitate and accelerate your production process with loading and unloading systems.

Used in industries such as automotive, heavy machinery and construction, these systems optimize material handling, streamlining production and improving operational safety.

why

choose forza laser?

GUARANTEE

REAL

We back you up with a solid, comprehensive warranty on your new FORZA Lyfter machine.

Your investment is protected!

REAL TECHNICAL SUPPORT

Technical support 7 days a week. Assistance response in 7 minutes. 24/7 technical support platform. On-site assistance in less than 24 hours.

Installation and training

Pre-installation visit. Delivery at your place of work. Integral installation.

WE ARE LEADERS IN LASER TECHNOLOGY

REAL TECHNICAL SUPPORT

Technical support 7 days a week.

Technical answers in 7 minutes.

24/7 technical support platform.

On-site assistance within 48 hours.

FULL WARRANTY

We back you up with a solid, comprehensive warranty on all consumables and components. Your investment is protected!

INSTALLATION AND TRAINING

Pre-installation visit.

Delivery to your site.

Electrical installation.

Pneumatic installation.

WHAT DOES YOUR FORZA LYFTER INCLUDE?

Platform with all the parameters you need for any FORZA machine and any material.

+800

SATISFIED CUSTOMERS IN AMERICA

CONTACT AN EXPERT

We value your time, we will get back to you as soon as possible.