Meet the new laser cutting solution

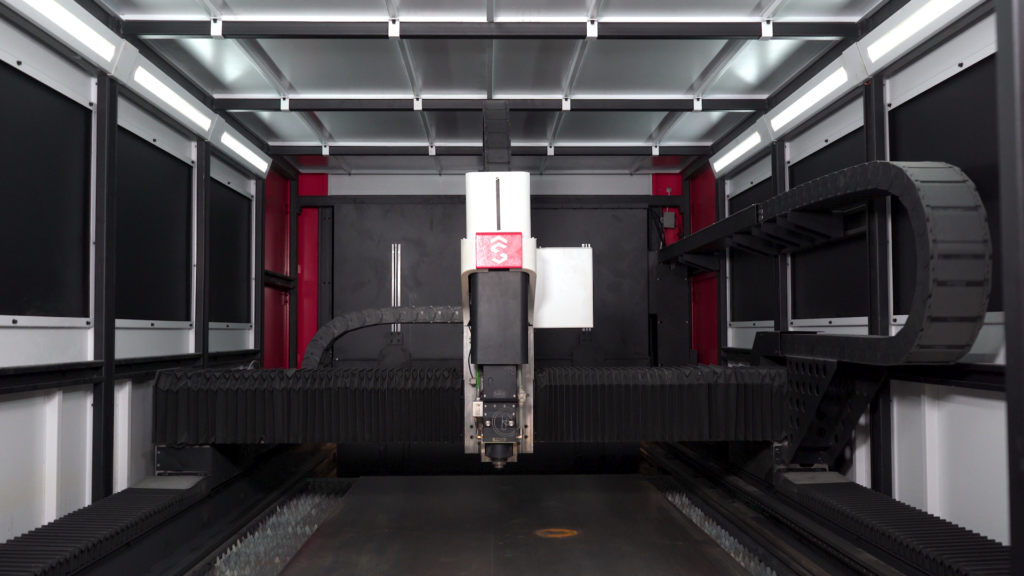

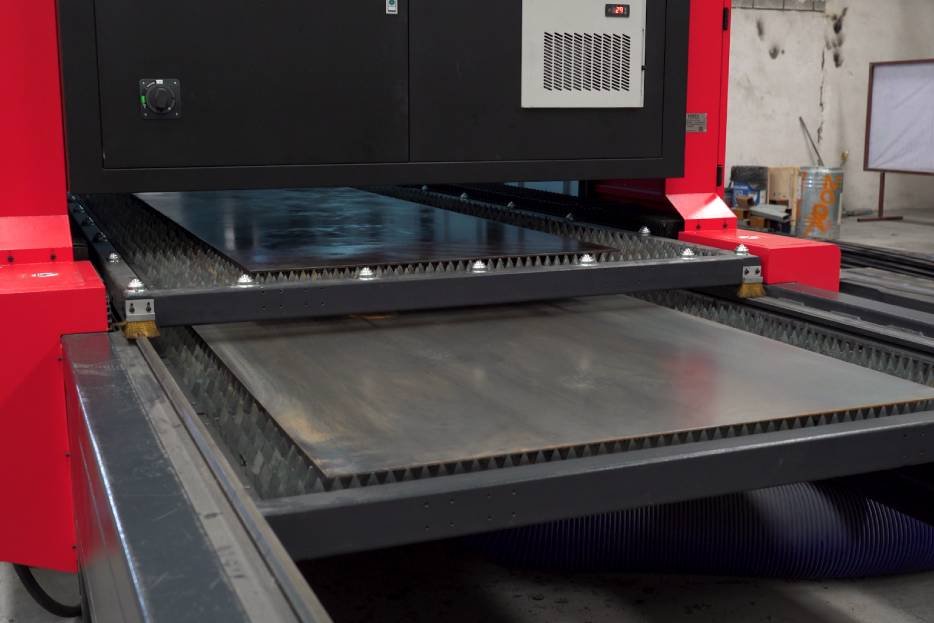

The FORZA Scanor is a high‑performance fiber laser cutter starting from 6000W, built with an enclosed dual‑bed design for continuous, clean production.

The FORZA Scanor is a high‑performance fiber laser cutter starting from 6000W, built with an enclosed dual‑bed design for continuous, clean production. Smart features like Gravity Cut, Find Edge, and Smart Focus deliver faster cuts, less waste, and flawless results on steel, stainless, aluminum, and more.

5-Year Warranty

| Feature | Scanor 6000W | Scanor 12000W |

|---|---|---|

| Laser Power | 6000W | 12000W |

| Nominal Cut (A36 Steel) | 3/4 in | 1−3/16 in |

| Max Cut (A36 Steel) | 1 in | 1−9/16 in |

| Max Cut – Stainless Steel | 5/8 in | 1−1/16 in |

| Cutting Area (Nominal) | 5 ft×10 ft | 5 ft×10 ft |

| Max Plate Load | 0.8 Ton | 2.2 Ton |

| Cutting Precision | ±1/256 in | ±1/256 in |

Specifications

Working area 5ft x 10 ft

Laser power 6000 W / 12000 W

| Material | Ideal Thickness | Maximum Thickness | ||||

|---|---|---|---|---|---|---|

| mm | in | Gauge | mm | in | Gauge | |

| ASTM A36 Steel | 19 | 3/4 | - | 25 | 1 | - |

| Stainless Steel ASTM 304 | 12 | 15/32 | - | 16 | 5/8 | - |

| Structural Aluminum ASTM 6061 | 9 | 23/64 | - | 12 | 15/32 | - |

| Brass C27200 | 7 | 9/32 | - | 10 | 3/8 | - |

| Galvanized Steel ASTM A653 | 3 | 1/8 | 12 | 5 | 3/16 | 6 |

| Material | Ideal Thickness | Maximum Thickness | ||||

|---|---|---|---|---|---|---|

| mm | in | Gauge | mm | in | Gauge | |

| ASTM A36 Steel | 30 | 15/32 | - | 40 | 1 (9/16) | - |

| Stainless Steel ASTM 304 | 17 | 21/32 | - | 27 | 1(1/16) | - |

| Structural Aluminum ASTM 6061 | 12 | 15/32 | - | 18 | 11/64 | - |

| Brass C27200 | 9 | 59/32 | - | 12 | 15/32 | - |

| Galvanized Steel ASTM A653 | 6 | 7/32 | - | 10 | 3/8 | - |

ROBUST EQUIPMENT OF HIGH POWER

Specifications Detail

Work area:

5ft x 10ft

(Entire sheet)

Laser power: 6000 W / 12000 W

Maximum cutting thickness 6000 W:

- Black steel: 1“

- Stainless: 0.62“

- Aluminum: 0.47“

Maximum cutting thickness 12000 W:

- Black steel: 1.96“

- Stainless: 1.73“

- Aluminum: 1.57“

DO YOU KNOW YOUR FORZA BENEFITS ?

FULL WARRANTY

We back you up with a solid, comprehensive warranty on all consumables and components. Your investment is protected!

REAL TECHNICAL SUPPORT

Technical support 7 days a week. Assistance response in 7 minutes. 24/7 technical support platform. On-site assistance in less than 24 hours.

Installation and training

Pre-installation visit. Delivery at your place of work. Electrical installation. Pneumatic installation.

WE ARE LEADERS IN LASER TECHNOLOGY

REAL TECHNICAL SUPPORT

Technical support 7 days a week.

Technical answers in 7 minutes.

24/7 technical support platform.

On-site assistance within 48 hours.

FULL WARRANTY

We back you up with a solid, comprehensive warranty on all consumables and components. Your investment is protected!

INSTALLATION AND TRAINING

Pre-installation visit.

Delivery at your place of work.

Electrical installation.

Pneumatic installation.

WE ARE LEADERS IN LASER TECHNOLOGY

REAL TECHNICAL SUPPORT

Technical support 7 days a week.

Technical answers in 7 minutes.

24/7 technical support platform.

On-site assistance within 48 hours.

FULL WARRANTY

We back you up with a solid, comprehensive warranty on all consumables and components. Your investment is protected!

INSTALLATION AND TRAINING

Pre-installation visit.

Delivery at your place of work.

Electrical installation.

Pneumatic installation.

APPLICATIONS OF THE FORZA SCANOR

Ideal for industries that require cutting thick materials quickly and accurately. It leaves a perfect finish, without burrs, so it does not need post-processing.

Thermostatic water heaters

Transformers

Electrical Panels

Ventilation systems

Refrigeration equipment

Technical Features

OBSTACLE AVOIDANCE

Its laser cutting technology allows you to avoid parts on the plate with maximum speed.

OPTIMIZED CUTTING

It takes advantage of motion inertia to reduce accelerations and optimizes trajectories, cutting up to 60% faster.

INTELLIGENT LASER CUTTING

Allows you to cut bent sheets, with a response speed of less than 10ms.

GUIDE MARKING

Marks and cuts, making it ideal for marking guides or detailing numbers for a folded purpose

MATERIAL SAVING

Find the origin and use the edges as part of the pieces.

AUTOMATIC LUBRICATION

It has an internal pump that sends oil to the rails to keep them always lubricated.

BRANDS THAT INNOVATED WITH FORZA SCANOR

BRANDS THAT INNOVATED WITH FORZA

Experience the power of a laser metal cutter SCHEDULE A FREE SHOWING

We value your time. We'll get in touch as soon as possible.