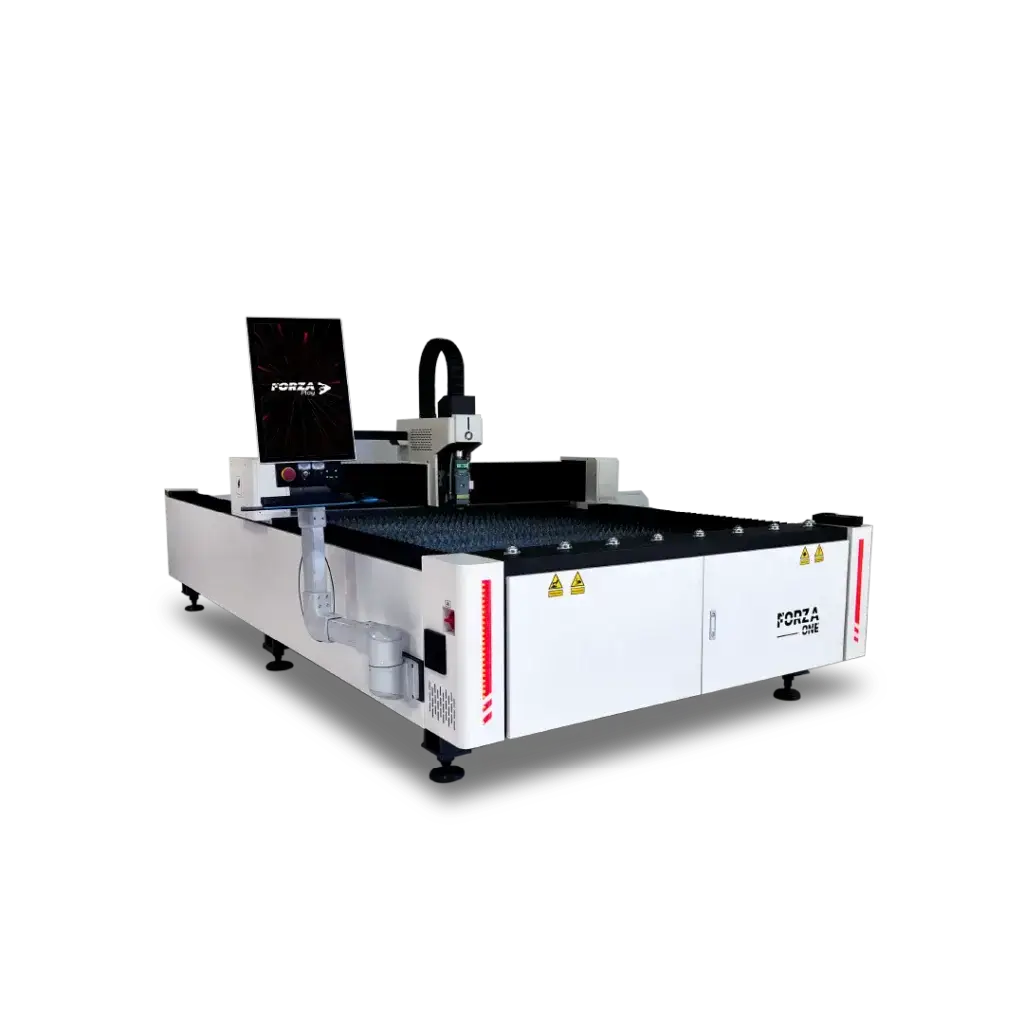

FORZA ONE

Advanced technology.

Work area: 3000mm x 1500mm

Power: 1500W

FORZA TAURUS

Single-body cutter with a robust structure for heavy plates.

Power: 6000 – 12000 W

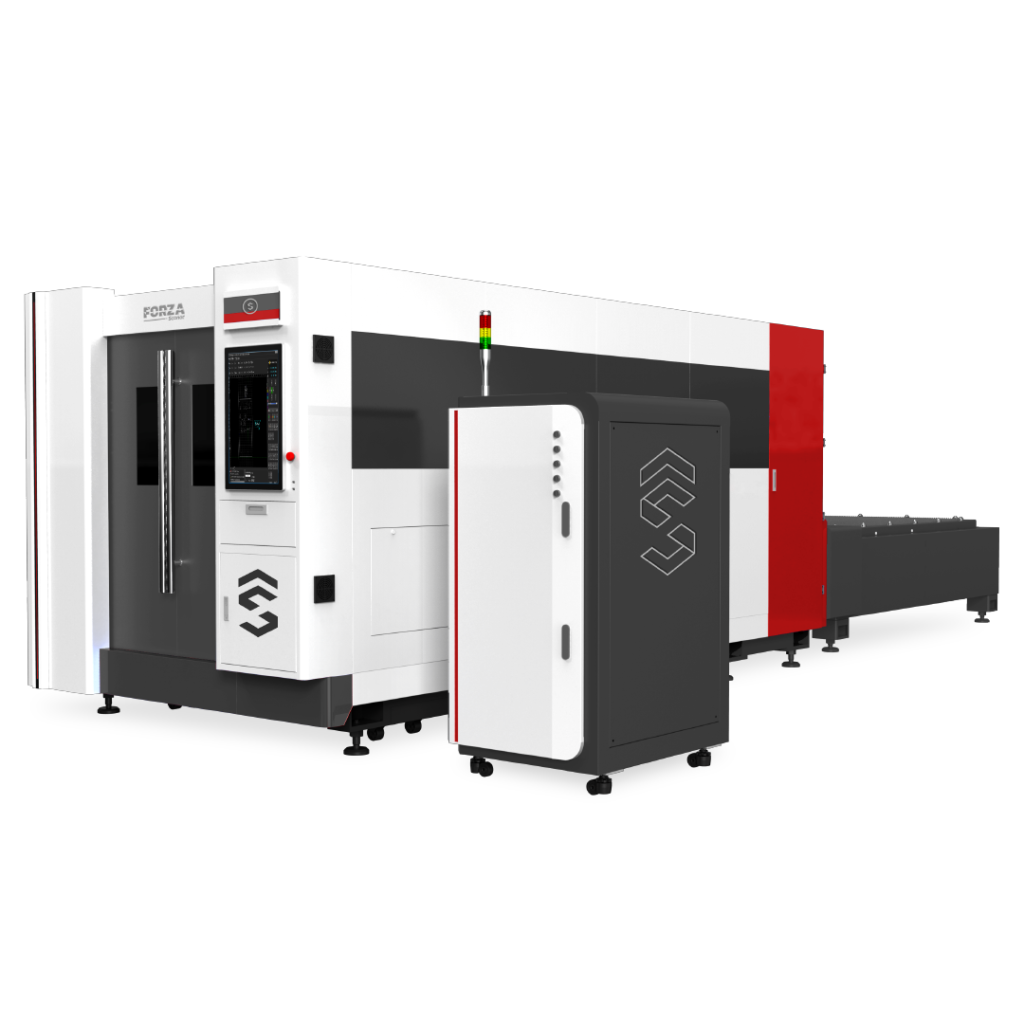

FORZA SCANOR

CNC cutting machine with interchangeable bed for non-stop productions.

Power: 6000 – 20000 W

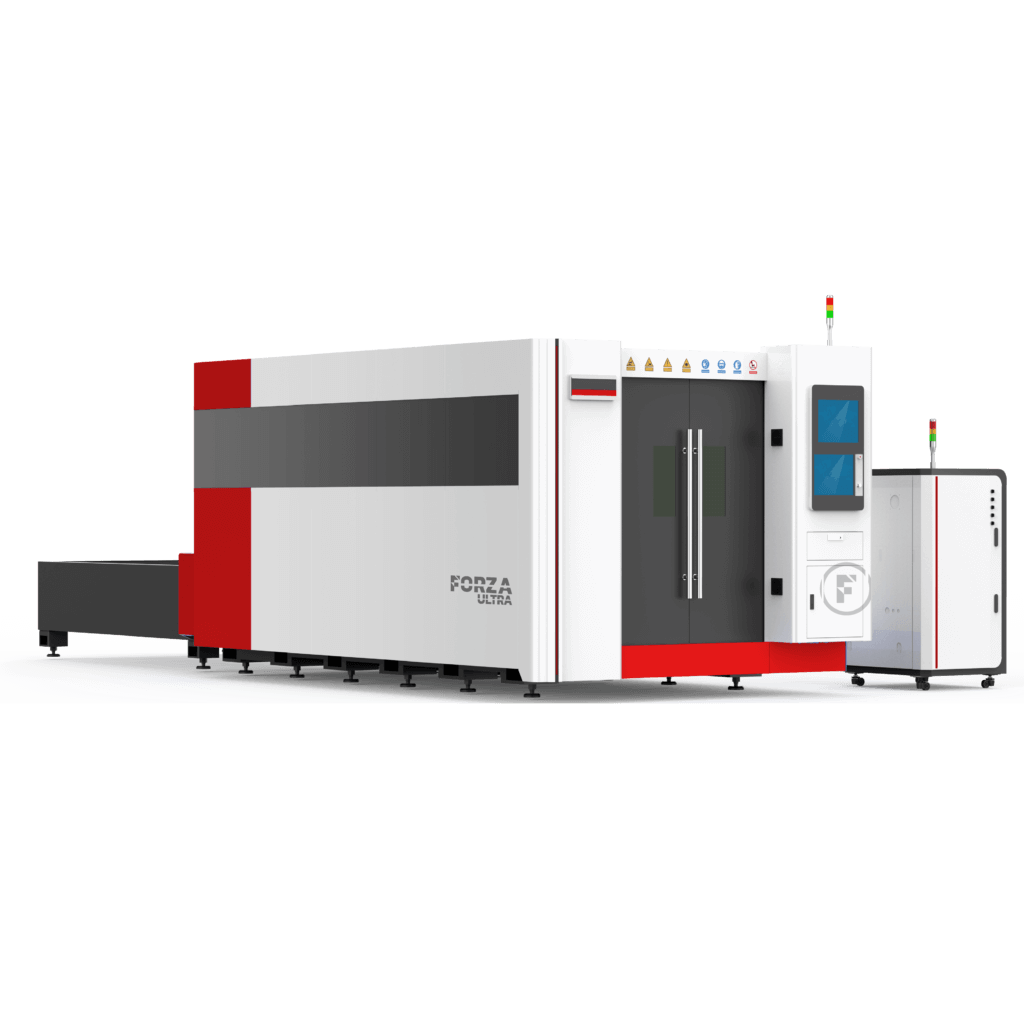

FORZA ULTRA

Robust version with interchangeable bed and graphite structure.

Power: 12000-20000-30000W

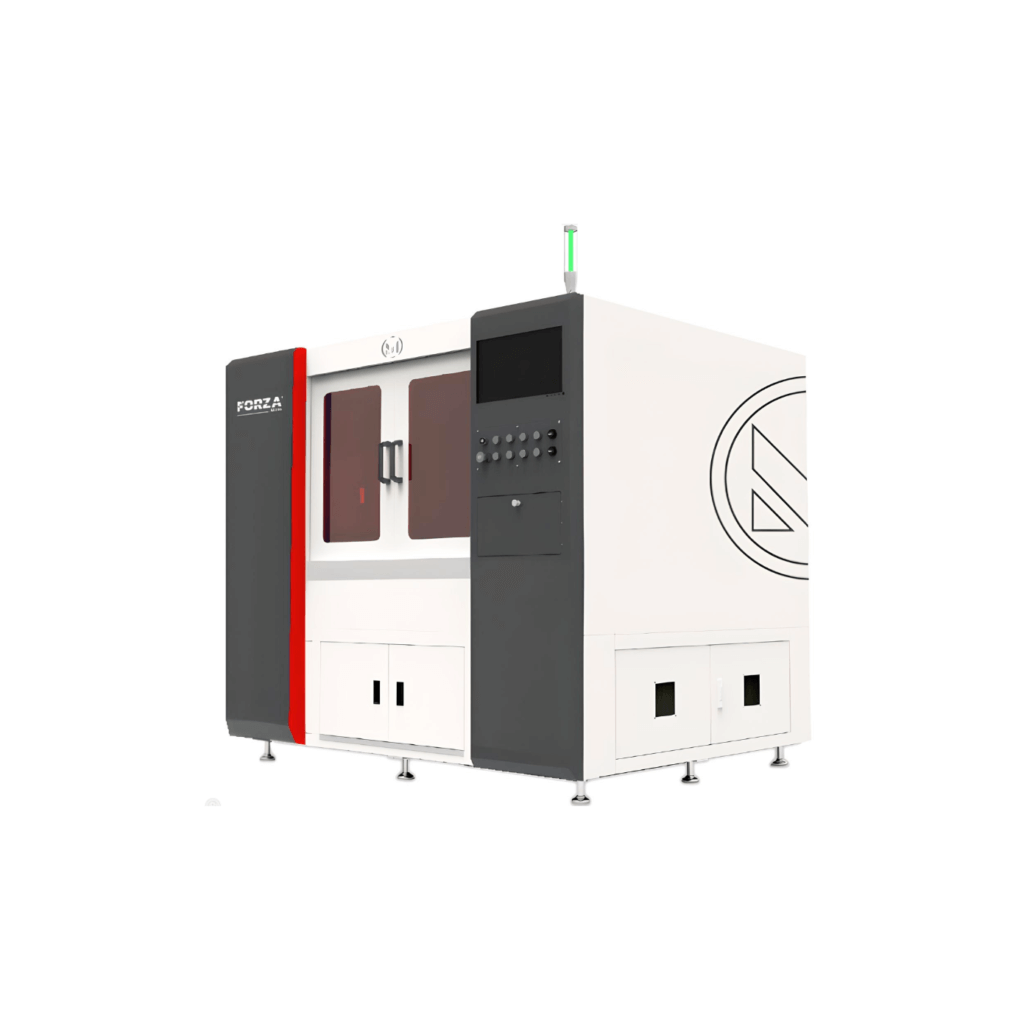

FORZA MICRO

With linear servomotors, the most precise machine for detail applications such as jewelry.

Power: 1500-3000W

FORZA GOLIAT

With gantry system to support heavier plates.

Power: 12000-20000-30000W

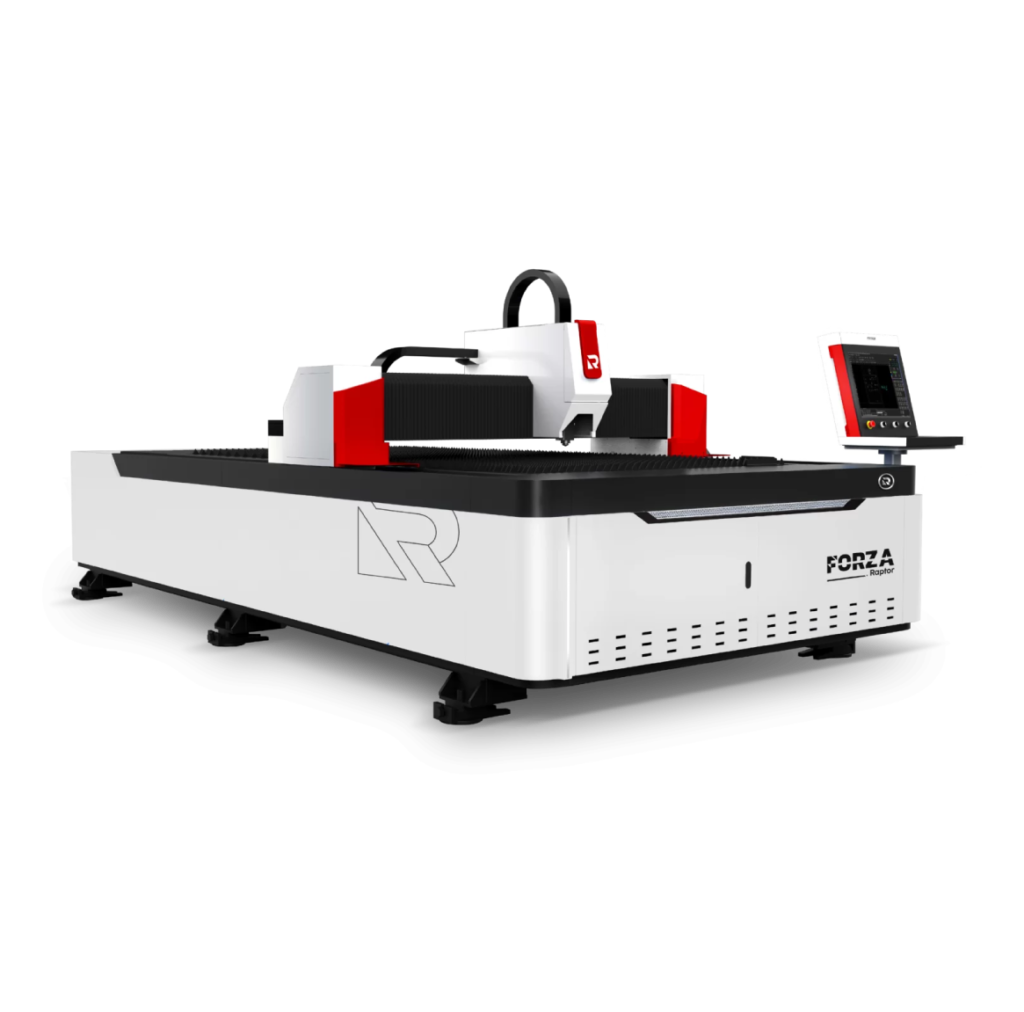

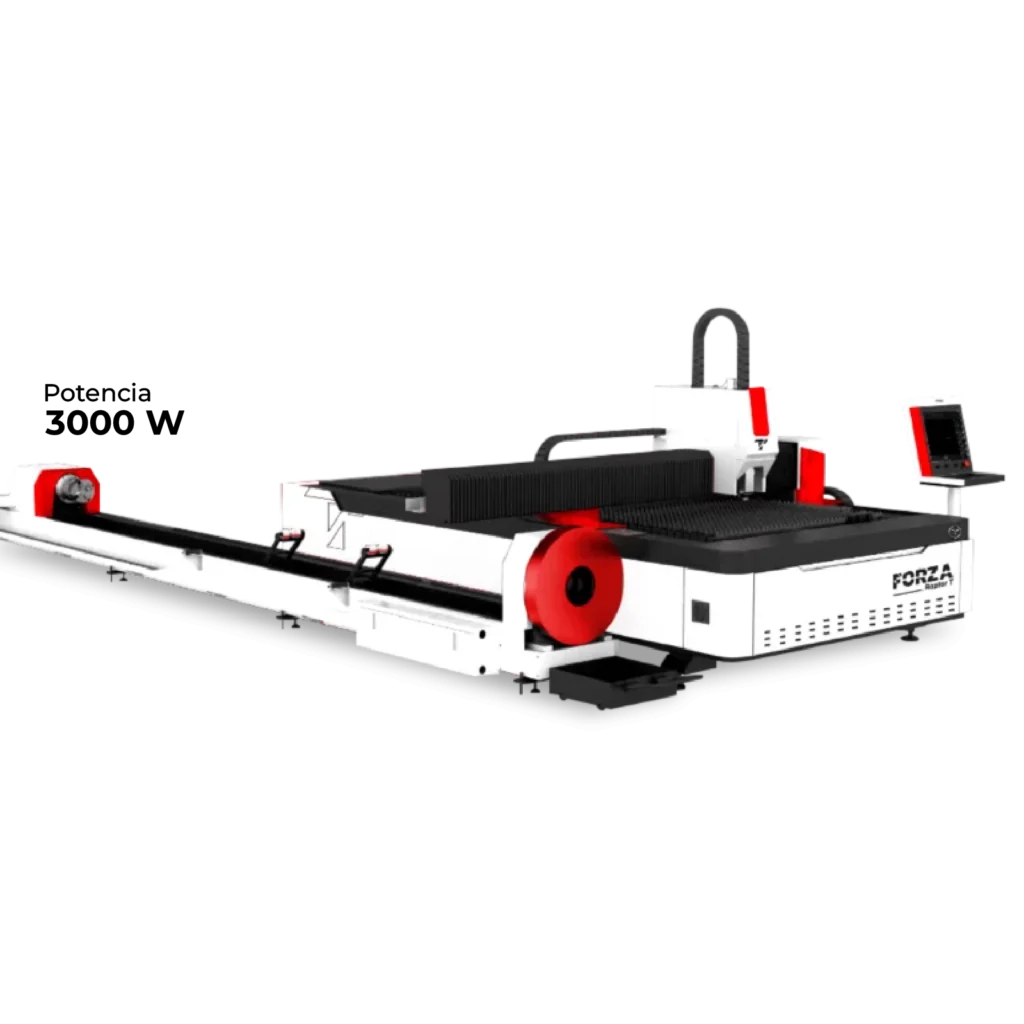

RAPTOR T

The ideal combination for single section plates and tubes.

Power: 1500-3000w

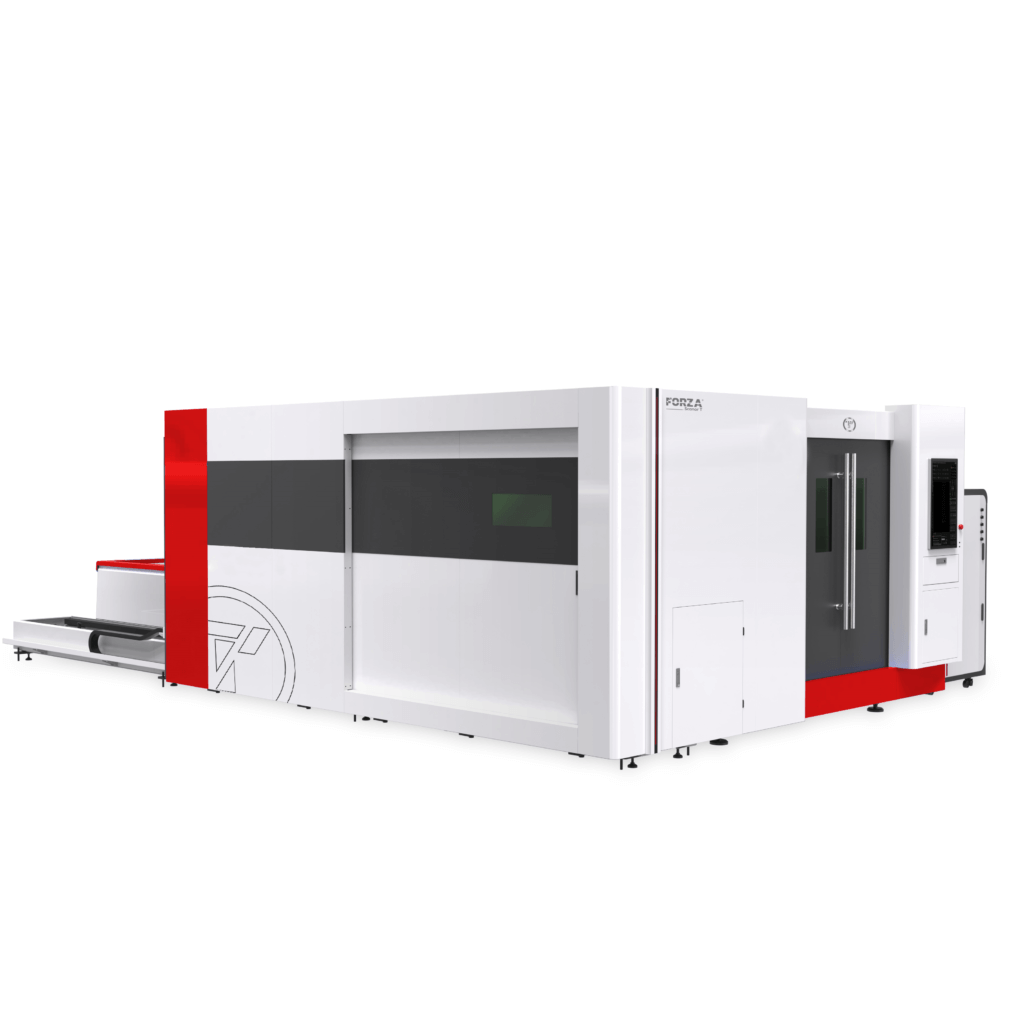

SCANOR T

Non-stop productions, interchangeable bed for plates and capacity for 6m tubes.

Power: 6000W

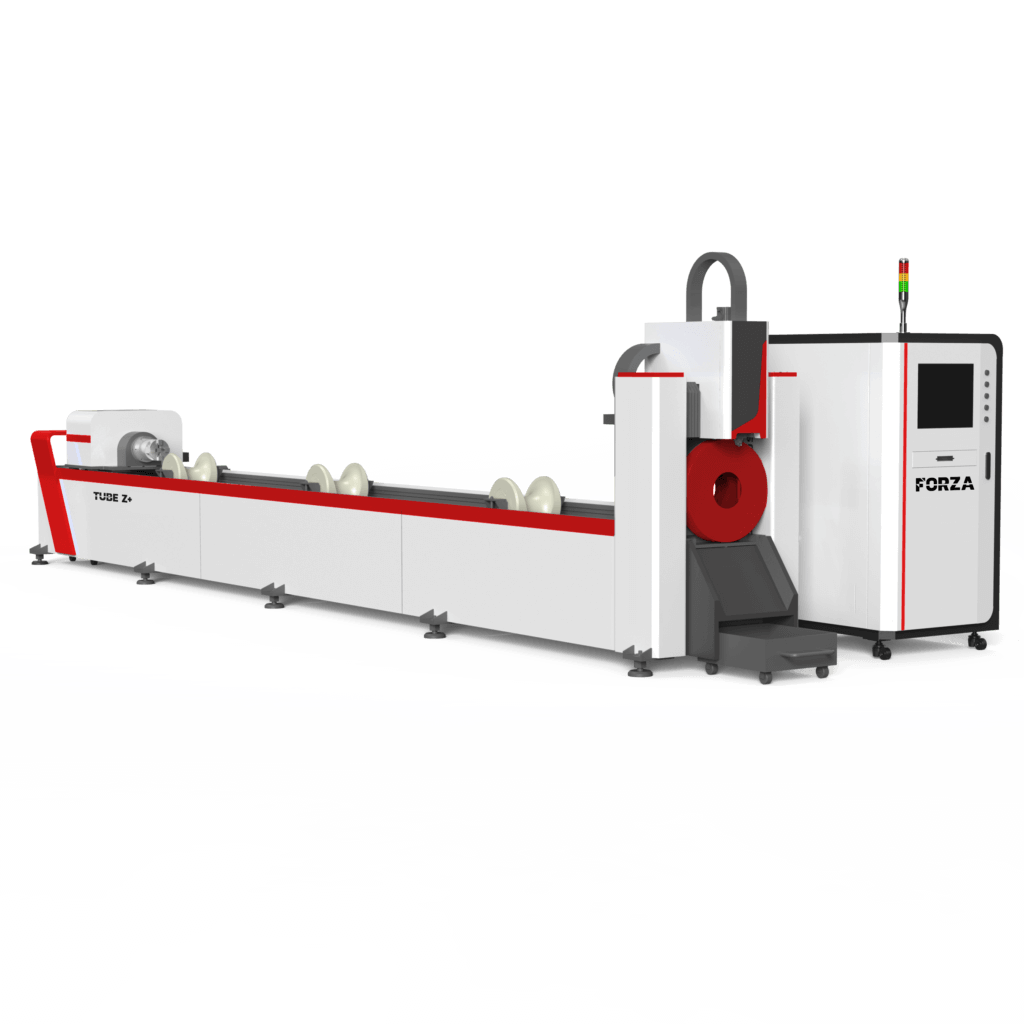

TUBE Z

The special machine for detail pipes from D 10mm to 220mm.

Power: 1500-3000-6000W

FORZA SOLDER

4 in 1 machine: Welds, cuts and cleans.

Power: 1500W/3000W

FORZA AURA

4 in 1 machine: Welds, cuts and cleans.

Power: 800W

COMPRESSOR X

220v 4-in-1 single-phase compressor with 5-stage filtration system.

Why FORZA Laser equipment?

local technical service

Technical support 7 days a week.

Technical answers in 7 minutes.

24/7 technical support platform.

On-site assistance within 48 hours.

guarantee

real

All components covered.

Real-time warranty.

installation

and training

Pre-installation visit.

Delivery at your place of work.

Electrical installation.

Pneumatic installation.

Why choose us?

local

tech support

Technical support 7 days a week.

Technical answers in 7 minutes.

24/7 technical support platform.

In-person assistance in 48 hours.

real

warranty

All components are covered.

Real-time guarantee

Installation

& training

Pre-installation visit.

Delivery to your workplace.

Electrical installation.

Pneumatic installation.

BRANDS THAT INNOVATED WITH FORZA LASER

F.A.Q

What is a CNC machine and how does it work?

CNC means computer numerical control, that is, a CNC machine is a tool controlled by computer software.

Then, the controller of the CNC machines receives instructions in the form of code from the computer and through its own software converts that information into electrical signals that activate the motors and start the components.

With CNC, the machines are exact and allow complex processes to be carried out such as 3D cutting tasks and precise engraving on different types of materials.

For example, with a CNC laser cutter, you can translate your designs into wood or metal, or make fully functional industrial parts.

We invite you to read our blog that will give you ideas about everything you can do with a laser cutter.

Is laser design and cutting a profitable business?

Since with a Forza laser cutter (formerly EC Machines) you can create anything you can imagine and provide laser cutting services or sell products you created, you can boost your existing business or start a new one.

According to a survey we conducted, several Forza customers have been able to create jobs thanks to their purchase.

Some machines produce income of more than $2,000 per month.

Forza Laser machines solve problems, we show you some of the situations that led our customers to trust us:

- Get started and achieve work independence

- Generate extra income so as not to depend on a single income

- Diversify your business and avoid outsourcing production

The improvements they achieved were significant.

For example: they were able to expand their catalog of products and services, improve their production times, gain greater clientele and improve their income, among other things.

What is a CO2 laser cutter?

The CO2 laser cutting printer is a CNC laser machine. It uses a CO2 laser beam to engrave and cut wood, MDF, plywood, chipboard, die-cutting, cardboard, acrylic, fabric, jeans, plastic, leather, paper, ABS, EPM, PE, PES, PUR, PVB, PVC, PUR, PMMA, PTFE and thin metals. It is widely used in industrial manufacturing and small businesses. A CO2 laser cutting machine specifically consists of a frame, a head, a lens, a mirror, a generator, a power supply, a water cooler, a control panel and a CNC system.

What is the price of a FORZA wood laser cutter?

Over time laser cutting printers have become more affordable. It used to be a tool only used in large factories. They can now be used in stores, bazaars, stationery stores and even homes.

The range of laser cutting printers starts from very economical to semi-professional and industrial models. In that sense, we can find on the Internet offers from USD 2000 and up. We recommend that you take into account not only the initial cost of the machine, but also the factors that in the long term could result in higher costs (e.g. maintenance, service life, components, etc.).

Our machines are priced from USD 3897 and in case you were wondering: yes, there are financing options.

At FORZA Laser we are committed to the quality of every aspect of the machines we manufacture, and we focus on providing a complete support experience. The customer is our neighbor.

Is it difficult to use a laser cutter?

Laser printers and laser engravers are so easy to use that you can start using them in an instant. We train our clients in person and online. However, the training mainly covers graphics software. If you know how to use a graphic design program, you are 90% ready because our printers are very easy to use and work almost like a regular printer.

Our Forza Laser customers or their employees operate the CNC machine tools themselves. In addition, our clients have 100% free and unlimited access to our premium vector platform for one year. premium vector platformready to use with their Forza machine.

What materials can I engrave and cut with a laser cutter?

The biggest advantage of starting a business with laser cutting and engraving machines is that they are very versatile. With a single printer, you can engrave and/or cut wood, acrylic, plastic, fabric, marble, glass and much more. We have guides in our line of technical supportavailable 24/7.

If we focus on choosing the best technology for manufacturing engraved products in various materials, there are many factors that make laser cutting more beneficial than 3D printing. It is true that 3D printers are useful for prototyping. But, the materials are not good enough to create parts. Laser cutting is a technology based on cutting a material to give a strong and durable finish.

Where can I find them?

Check our contact page and our social networks. There you will find all the information about FORZA Laser.